Stud Tensioners

FASTORQ's stud tensioners are the fastest in the industry and cut job time by 90 percent.

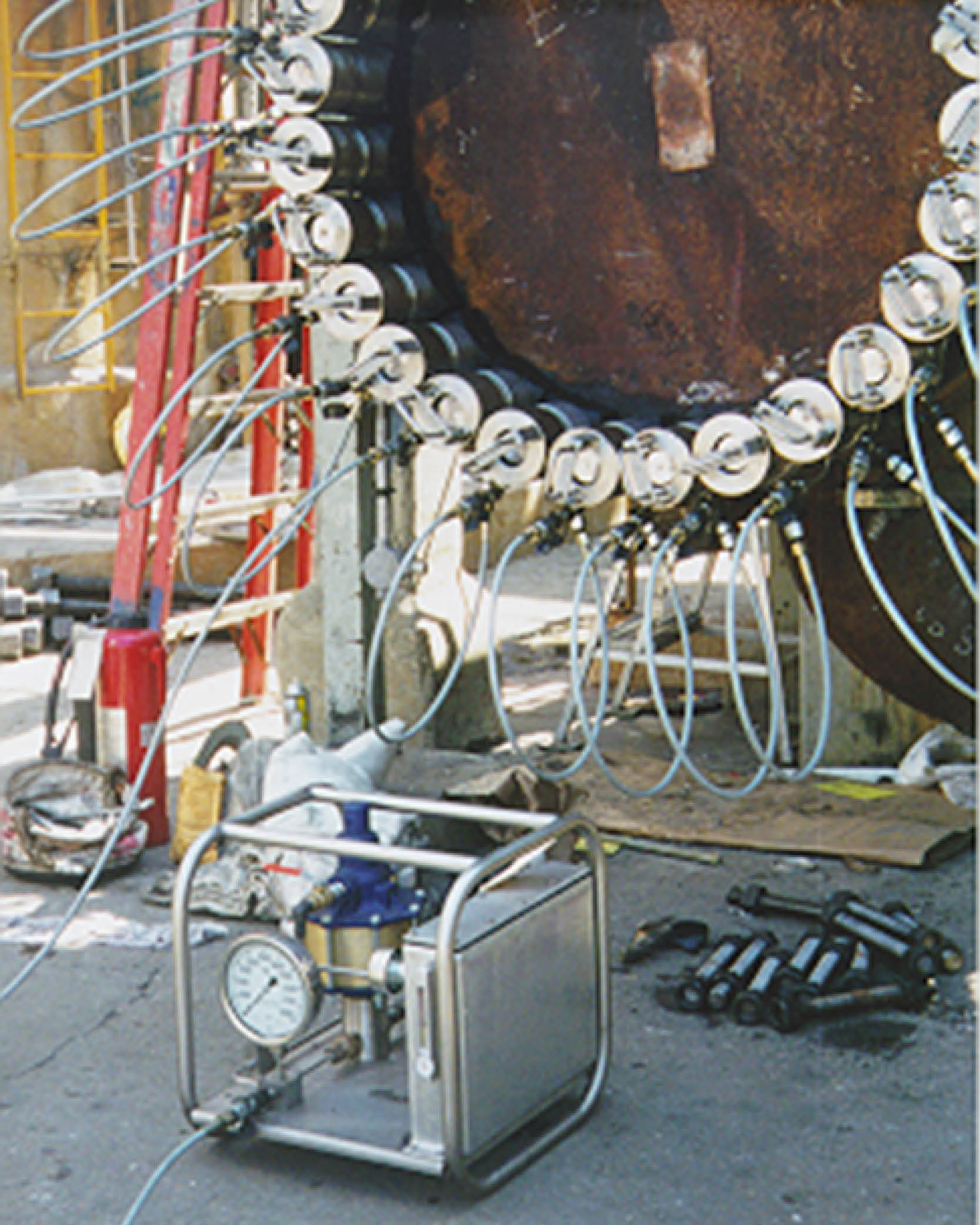

ZipTENSIONER is the ultimate in reliability and speed for bolt loading applications. The one-piece design provides 100 percent coverage on the same side of the flange and simultaneous tension of multiple fasteners. By evenly loading on all fasteners in the joint, ZipTENSIONERs eliminate elastic interactions, provide uniform bolt load and achieve leak-free joints.

The FAST (fully automated stud tensioner) System operates hands-free from a Hydraulic Contol Console operating on a rig hydraulics to control all functions for the tool, maximizing safety benefits.

Designed to provide subea, nuclear, and wind industries with the latest technology and flexibility. The ZipTENSIONER simultaneously tensions multiple fasteners, cutting the required time by conventional tensioners in half. Installation is simple, with the ZipTENSIONER compact, lightweight and just one piece.

ZipTENSIONER Nuclear

• Self-lubricating seals provide unlimited shelf life

• Operating pressure up to 30,000 PSI

• Low coefficient of friction (.04)

• Spring-energized seals mean permenant elasticity

• Compact and lightweight

ZipTENSIONER Subsea

• Fully automated single unit slides on and off bolt

• Cuts dive time up to 90%

• Fastest same side flange coverage

• Revolutionary ZipNut Technology

• Compact and lightweight

ZipTENSIONER Wind Turbine

• Quick, safe and accurate tool

• Simultaneous loading of multiple threaded studs and bolts

• Available with ZipNut Technology

• Long working stroke (.625”) standard

• Captive nut rotator, two hyrdraulic ports

• Over-stroke indicator

• Models to provide maximum tension from 86,800 pounds at 10,000 PSI to 134,573 pounds at 9,600 PSI hydraulic pressure

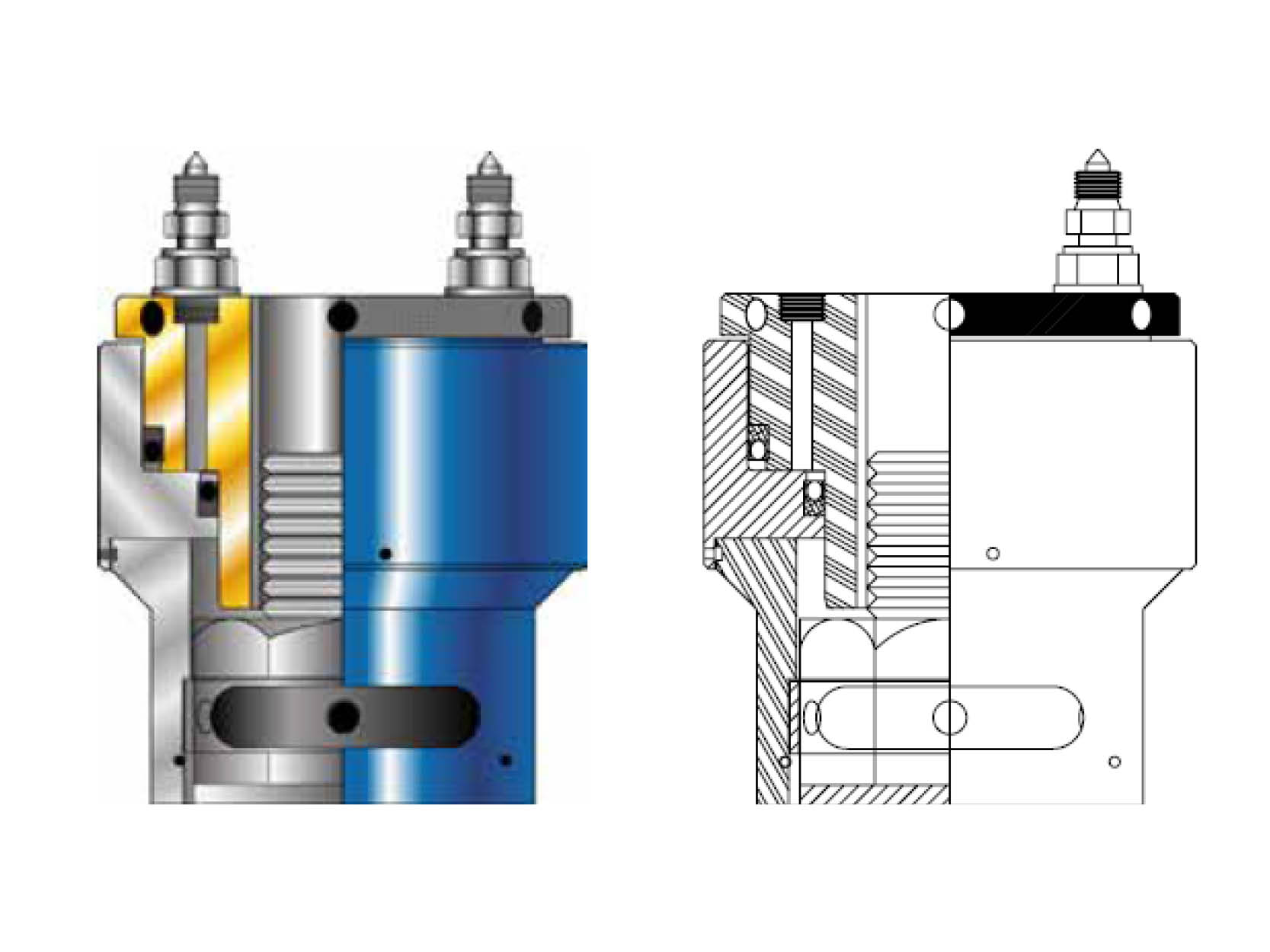

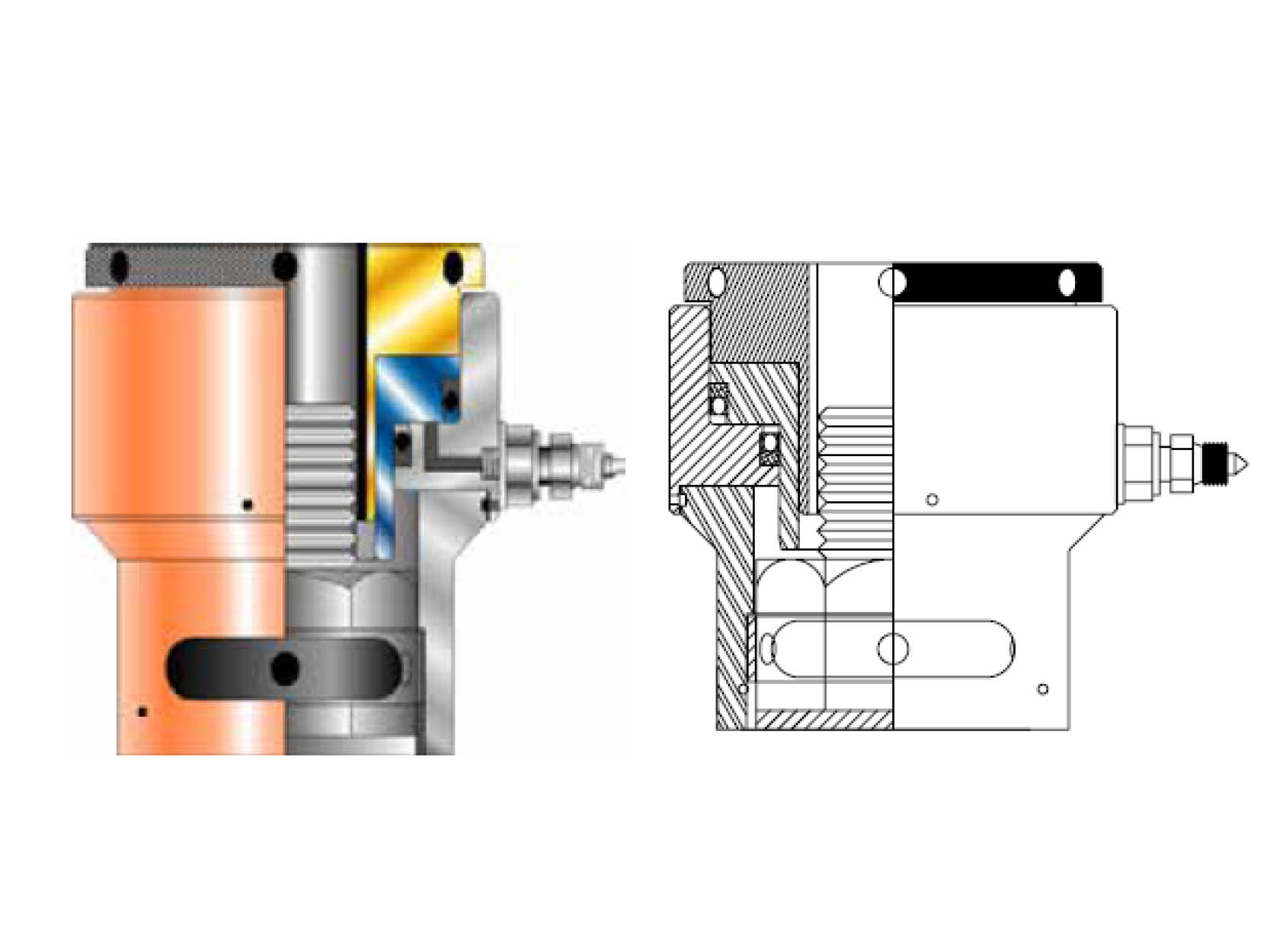

The F.A.S.T. (Fully Automated Stud Tensioner) system was designed to increase safety, save time, and maximize joint integrity compated to hydraulics torque wrenches and conventional stud tensioners for bolt tightening and loosening operations. F.A.S.T utilizes patented ZipNut Technology to provide tensioning and de-tensioning of fasteners in time critical joints such as drilling risers, subsea piping flanges and pipeline repair clamps.

The ability to slide on and off the bolts allows F.A.S.T. to operate hands-free with an operator at a remote Hydraulic Control Console with a built in pump to control all functions for the F.A.S.T. This maximizes safety as no personnel need be anywhere near tool when it is operating. The hydraulic pressure from the Hydraulic Control Console to the F.A.S.T. is 2,000 psi. or less making it much safer than the 22,000 psi. required for conventional stud tensioning systems. An intensifier is located inside the tool envelope to deliver the required pressure to the tensioner load cells. Safety is further ensured in the event of hydraulic seal failure by diverting the fluid inside the tool envelope.

Because F.A.S.T. is a tensioning system, it has none of the problems associated with hydraulic ratcheting torque wrenches. Utilizing ZipNut Technology and double-acting hydraulic load cells, it also eliminates the drawbacks of conventional tensioners. 100% coverage means loading all the bolts in a connection simultaneously and thus eliminating elastic interactions and the Load Loss Factor. By reducing the hydraulic load cell diameter and increasing the pressure, the tensioners fit better side-by-side to achieve 100% coverage on the same side of the flange.

F.A.S.T. must be used with a delivery system such as an articulating arm, rail driven frame or overhead lift system. The delivery system must be able to move up and down, in and out, and side to side. The Hydraulic Control Console is responsible for the following tool actions.

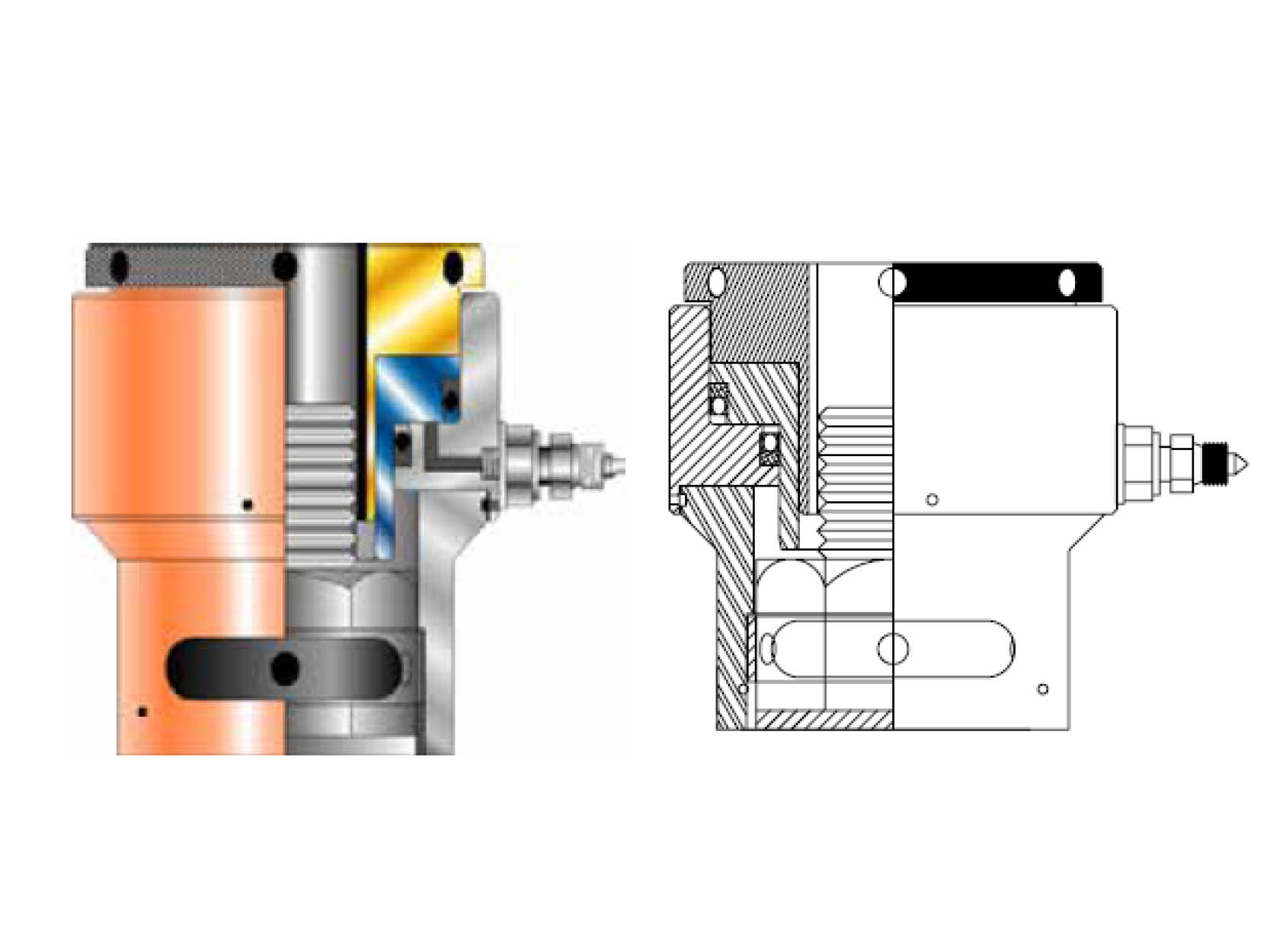

The quick, safe and accurate method of simultaneously loading multiple threaded fasteners is with FASTORQ Stud Tensioners. A bolted joint is clamped together by the permanent load applied to its optimum specification. If the bolt is loaded (tensioned) improperly, it will not do the job or it will not last on the job. Either way, the bolt fails. Accurate bolt tensioning is critical to the integrity of the joint. FASTORQ reduces the variable risk in critical bolting situations by allowing quick, safe and accurate tensioning. FASTORQ Stud Tensioners are available in several models. FASTORQ offers traditional models, fixed or variable and the exclusive ZipTENSIONER.

Fixed Model Features

• Self-lubricating seals provide unlimited shelf life

• Seals are high-performance polymers, FDA approved for food industry specifications

• Operating pressure up to 22,000 psi and temperatures from -400°F to +500°F

• Low coefficient of friction - 0.04

• Longer life seals provide better performance, fewer replacements

• Spring-energized seals provide permanent elasticity

• Variable models feature interchangeable components, affording greater coverage at lower cost

• Metric Sizes available

Variable Model Features

• Self-lubricating seals provide unlimited shelf life

• Seals are high-performance polymers, FDA approved for food industry specifications

• Operating pressure up to 22,000 psi and temperatures from -400°F to +500°F

• Low coefficient of friction - 0.04

• Longer life seals provide better performance, fewer replacements

• Spring-energized seals provide permanent elasticity

• Variable models feature interchangeable components, affording greater coverage at lower cost

• Metric Sizes available

Operation and Maintenance Manual