SUBSEA/ROV SOLUTIONS

SUBSEA/ROV

SOLUTIONS

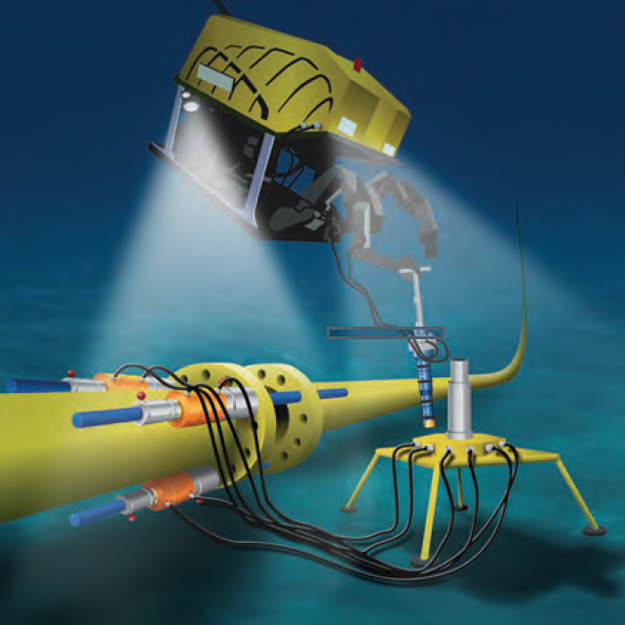

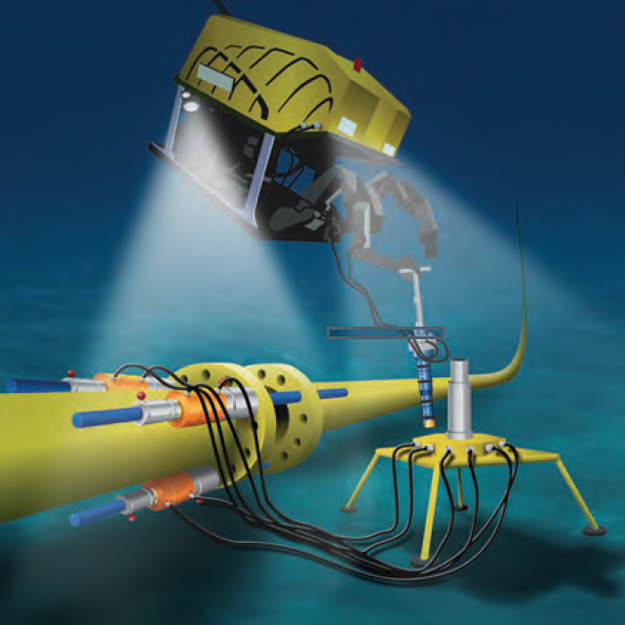

Subsea Remotely Operated Vehicles (ROVs) are cruicial for underwater operations, utilizing advanced torque tools for tasks like valve operation, bolting, and repairs. Our products interface with ROVs through standardized and robust connections, providing precise control and feedback for safe and effective use. Designed to withstand high-pressure and corrosive environments, FASTORQ products enable ROVs to perform critical maintenance and intervention tasks, enhancing efficiency and reducing the need for human divers. The modularity and integration of these tools with other subsea systems ensure comprehensive and coordinated underwater operations. Dig deeper and learn more about our subsea/ROV solutions.

OFFSHORE & SUBSEA

BOLTING TOOLS

SpinTORQ

Unlike traditional ratcheting hydraulic wrenches, SpinTORQ provides continuous 360-degree rotation, making it up to 100x faster at turning nuts. This speed allows subsea flange make-up in under 30 minutes, saving dive time and reducing costs. Its durable design and 2,500 psi system ensure reliable, efficient performance for faster turnarounds and significant cost savings.

Double Cutting AutoSPLITTER

Some jobs just call for speed. The Double Cutting AutoSPLITTER works by eliminating the need to move the nut splitter to a second position 180-degrees from the first to break the nut from the stud. It cuts both sides of the nut in one stroke of the cylinder.

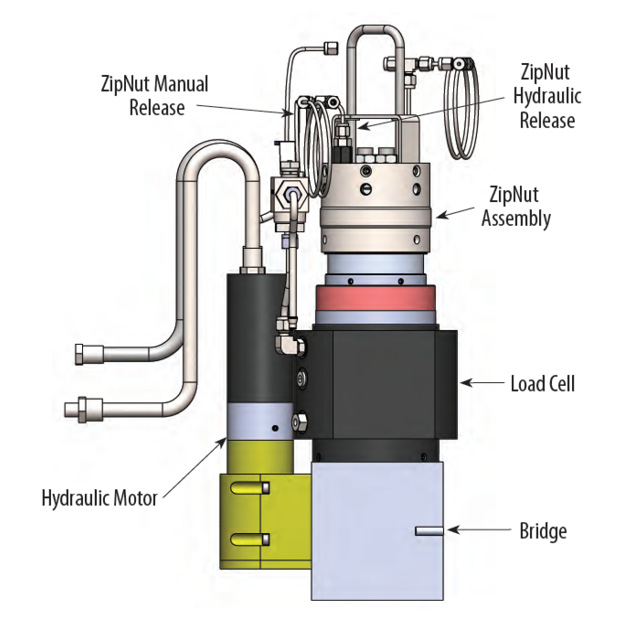

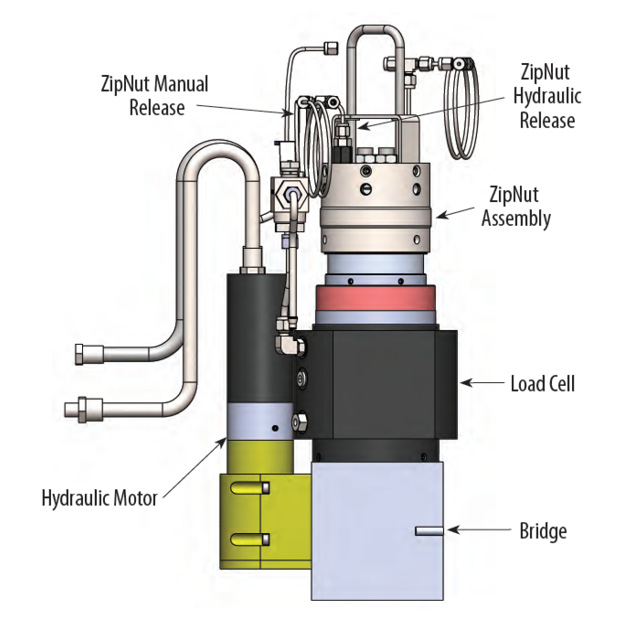

ZipTENSIONER

The ZipTENSIONER is the only diverless tensioner on the market. It simply slides on and off the bolt making installation and removal with an ROV possible in a single integrated unit. This is a huge time saver for nuclear applications and other limited exposure environments.

F.A.S.T.

The Fully Automated Stud Tensioner (FAST) is designed for a 21-3/4" 5,000 psi flange with 24, 2" diameter bolts, currently operating in the Gulf of Mexico. It operates hands-free via a Hydraulic Control Console, ultilizing hydraulics to control all functions. The tools features wings that wrap around the riser and can be delivered via an articulating arm, rail-driven frame, or overhead lift. The entire process is completed in under 4 minutes.

ZipPULLER

This powerful flange puller was designed for quick and efficient flange alignment, pulling, or mating on land or underwater. Available in 30-60 ton models, it uses ZipNut technology for fast installation and removal, with quick release levers for easy operation. Ideal for subsea applications, it can be operated by ROVs, hard suits, or divers at any depth. Built with corrosion-resistant materials, ZipPULLER delivers uniform flange make-up and can be powered by a single hydraulic unit.

ZipNUT®

First developed for NASA for use on the Space Shuttle, International Space Station and Hubble Telescope, ZipNuts are designed to eliminate the time-consuming motion of threading a traditional nut on a bolt in applications where speed, accuracy and reliability are vital.

STREAMLINE YOUR OPERATIONS WITH OUR SUBSEA SOLUTIONS

Subsea Remotely Operated Vehicles (ROVs) are crucial for underwater operations, utilizing advanced torque tools for tasks like valve operation, bolting, and repairs.

Our products interface with ROVs through standardized and robust connections, providing precise control and feedback for safe and effective use. Designed to withstand high-pressure and corrosive environments, FASTORQ products enable ROVs to perform critical maintenance and intervention tasks, enhancing efficiency and reducing the need for human divers. The modularity and integration of these tools with other subsea systems ensure comprehensive and coordinated underwater operations.

Dig deeper and learn more about our Subsea/ROV solutions!

ZipTENSIONER

Driveless Stud Tensioner

- Fully automated single unit slides on and off bolt

- Cuts tensioning time up to 90%

- Only diverless tool in the world

- 100% same side flange coverage

- ROV friendly

- Revolutionary ZipNut® Technology

The ZipTENSIONER is the only diverless tensioner on the market. Others make this claim with tensioners utilizing split nuts that must be manipulated by the ROV. This is very difficult if not impossible.

The ZipTENSIONER simply slides on and off he bolt making installation and removal with an ROV possible in a single integrated unit.

The ZipTENSIONER is also a huge time saver for nuclear applications and other limited exposure environments.

ZipPULLER

Subsea Flange Puller

- Fast & easy

- Largest load capacity in the industry

- ROV & diver friendly

The ZipPULLER flange puller makes fast work of pulling, aligning or mating a wide range of flange sizes on land or underwater with the largest load capacity pulling system around.

Available in 30-ton (6-inch) and 60-ton (5-inch) stroke models, the ZipPuller powers that difficult flange into place.

Using ZipNut Technology, ZipPULLER slides right over the threaded rod during the retraction process. In addition, it can be pulled off tandard threaded rods and has quick release levers to open and close the ZipNuts for fast installation and removal. No more time-consuming tightening of nuts and bolts.

Well-suited for subsea flange pulling and alignment, the versatile ZipPULLER is perfectly suited for use with ROVs, hard suits and divers since it can be operated at any depth.

Designed to provide uniform flange make-up with multiple units and a single hydraulic power unit, ZipPULLER’s parts are stainless steel, nickel-plated or coated to provide corrosion

protection.

ZipPULLER comes with FASTORQ’s Total Assurance Guarantee and 1-Year Warranty.

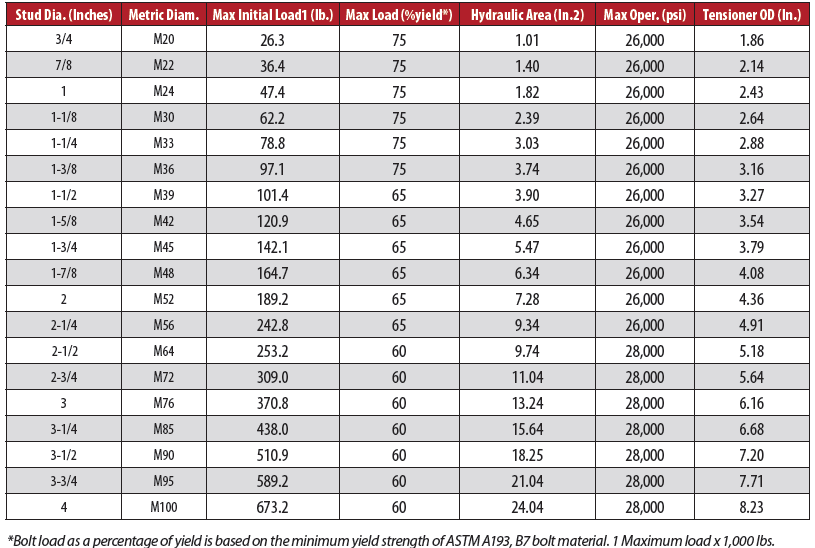

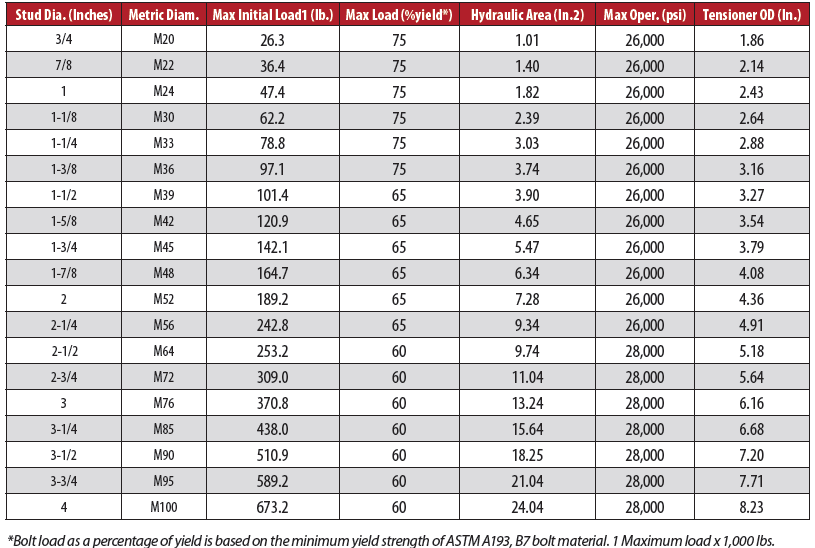

ZipNut

Space Age Meets Energy Industry

- Revolutionary technology

- Originally developed for NASA

- Fast & efficient

- Durable

- Reduces time & labor costs

- No cross-threading

- Custom sizes & materials available

The technology works like this: A ZipNut can be installed by simply pushing it onto a bolt in one motion, eliminating the difficulty of threading a traditional nut. When the ZipNut reaches the end of the bolt’s threads, it can then be tightened by simply twisting it.

This innovation improves both the speed and accuracy of the task. That translates into a big savings in many work environments, not only in dollars, but sometimes even in lives. One such live-saving use is in mechanisms for extracting victims of auto crashes, building collapses, cave-ins and construction accidents. When time is of the essence, the quick connect and release can mean the difference between life and death.

Now produced in a number of different sizes and materials – such as stainless steel, aluminum, titanium, Ferralium, brass and even plastic – the earth-bound industries that benefit from them are as diverse as the materials themselves. ZipNuts can be found in medical equipment, tire manufacturing machines, subsea pipe laying equipment, power plants and fire hoses, just to name a few.

These fastening mechanisms are used in the same ways as their traditional counterparts, but with the added flexibility of speedy installation and removal, and in some cases, even added strength. One such strength benefits in high-pressure connections, where the pressure actually

works with the connector to make it more secure.

Another big advantage ZipNuts have over traditional threaded fasteners is their ability to work in spite of problems like rust, paint and damage that would normally prevent traditional connections from being made.

ZipNuts also come in a Double Zip® option that slides onto the nut in the same manner as the original, but give users the option to also remove the nut the same way with one quick turn and slide off he bolt.

ZipNut Technology is a viable option for many industries where speed, accuracy and reliability are important and even life saving. Additionally, robotic adaptability makes ZipNuts and ZipNut Technology tools ideal for subsea, land-based, wind and nuclear applications.

Standard ZipNuts replace heavy hex nuts and on standard bolts.

When you are ready to step up to the fastening technology NASA trusted with its equipment, give FASTORQ a call and ask for the one and only ZipNut Technology.