Radiation, intense heat and deep-water subsea environments are extremely dangerous to humans. Fortunately, the dark days of putting people in life-threatening danger unnecessarily are over thanks to innovative ZipNut Technology.

Through unique adaptations, standard tools are being transformed and now remove human interaction in dangerous areas. They’ve been found to make work safer and faster in such industries as energy, nuclear, fire/rescue and aerospace.

The ingenious technology behind ZipNuts allows them to replace the time-consuming and repetitive motion of threading regular nuts thanks to a special design where the ZipNut’s spring-loaded thread segments expand as they travel down the bolt. When the ZipNut is tightened with a quick turn, those same thread segments are forced onto the threads of the bolt thanks to the complementary geometry between ZipNut’s housing and its thread segments.

By taking the unparalleled speed of the ZipNut, which was originally developed for NASA for use on the Space Shuttle, International Space Station and Hubble Telescope, and applying it to many tools in a variety of applications, work not only becomes safer but more efficient.

See these products and more at Booth #3301 at the 2017 Offshore Technology Conference

Reliant Park | Houston, Texas | May 1-4

ZipNut Technology Tools in Action

ZipNuts have given birth to tools that are game changers in many industries. But, the subsea industry is a perfect example of where ZipNut Technology is changing how business gets done.

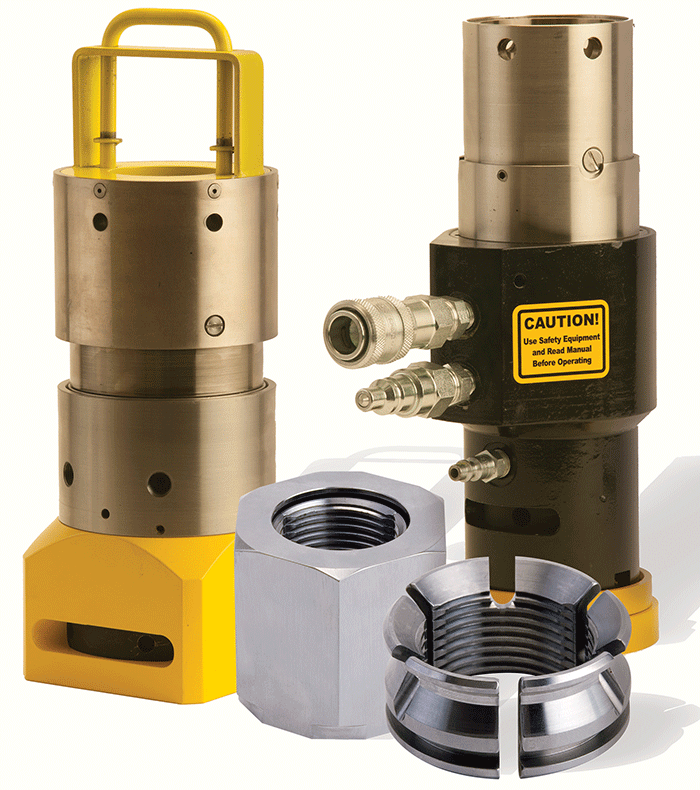

FASTORQ developed a line of ZipNut Technology Tools that adds safety to hazardous environments but also brings increased speed and production capability with such tools as the ZipTENSIONER, F.A.S.T. System, ZipPULLER, ZipLIFT and AutoZIP VIV Mechanism Fastener.

ZipTENSIONER

The ZipTENSIONER is a stud tensioner that uses Double ZipNut Technology to provide 100 percent, same side flange coverage and reduces tensioning time by up to 90 percent. This is accomplished with higher pressure and reduced load cell size. Elastic interactions are eliminated, and the old standard of twisting and turning heavy and awkward standard stud tensioners is a thing of the past. ZipTENSIONERs are compact, lightweight and simply slide on and off the stud, even past damaged and corroded bolts, to provide accurate tension with incredibly impressive speeds. The time reduction when using ZipTENSIONERs can save hundreds of thousands of dollars in just one use.

F.A.S.T. System

Take the ZipTENSIONER and ZipNUT Technology one step further, and you get the F.A.S.T. (Fully Automated Stud Tensioner) System. This system takes the human interaction of tensioning and completely removes it. Controlled by a single hydraulic power console, this system incorporates multiple ZipTENSIONERs into one frame that is lowered onto all of the studs on the same side of a flange. With the push of a button, all of the tensioners are simultaneously energized and the nuts are turned down. Once finished, F.A.S.T. http://www.fastorq.com/uncategorized/revolutionary-technology-protects-humans-from-hazardous-environments/ http://www.fastorq.com/uncategorized/revolutionary-technology-protects-humans-from-hazardous-environments/removes just as easily as it went on.

Come by booth #3301 and learn about the many ways ZipNut Technology is bringing safe and efficient tools to the oil industry! Here’s a link to the OTC Official Website .

You can all see demonstrations of ZipNut Technology products on the following videos:

ZipTENSIONER & F.A.S.T. System overview

You can also get more information about FASTORQ’s full line of innovative bolting technology tools online at www.fastorq.com, by calling 281.449.6466 or 800.231.1075.

APR